欢迎使用 WordPress! 这是一篇示例文章。 编辑或删除它,开启您的博客之旅。 如需在此处添加更多内容,请点击左上角的小加号图标。 在这里,您可以找到现有的 WordPress 区块和样板选择,可满足您在内容创建方面的各种需求。 此外,请别忘了查看“列表视图”:点击加号图标右侧的图标,您就会看到一个规整且易于查看的列表,其中列出了您文章中的区块和样板。

-

-

How long do you expect a factory to producing 1500 pieces of clothing? For suppliers of fast fashion giants like ZARA and SHEIN, it takes 5 to 7 days.

But for factories in Kanglu area in downtown Canton, it is within 48 hours. Even the order quantity can be reduced to a single piece of fabric. These perfectly meet the first principle of fast fashion – launching more clothing styles with lower inventory.

However, this supply chain is declining. Due to the shrinking consumption for clothing, its orders are decreasing and its workers are leaving. Early November should be a time when factories busy making winter clothes, but more than 80% of them were not operating.

*workers in Kanglu sitting on roadside, who have no jobs to do

Who is most affected by the declination? Factory owners and workers. The impact on the upstream (fabric factories) and downstream (clothing sellers) of clothing supply chain is much smaller. This is because China’s clothing industry is of overcapacity – it yearns for customers, not factories.

48-hour Supply Chain

From order to shipment, Kanglu factories can do it within 48 hours, sometimes 36 hours.

E-commerce sellers and wholesalers are in desperate need of such a flexible supply chain: the sales volume of clothing styles fluctuates greatly. Clothes that originally sold 100 pieces can rise to thousands. This makes it difficult for sellers to cooperate with large-scale factories.

“It’s risky for small-scale sellers to give orders to large factory. If your order quantity is only 500, you can’t fit in,” explained a live-streaming seller on Douyin, Chinese version of TikTok.

How does such a high-speed supply chain come to exist?

Two reasons explain it:

Firstly, Kanglu area is very close to the upstream and downstream of the clothing supply chain.

It is adjacent to Zhongda Fabric Market, the largest one in South China. It is 5 kilometers south to Shahe Clothing Wholesale Market, whose wholesalers bring orders from all over the country.

Secondly, there are more than 500,000 clothing workers living in the 5-square-kilometer area. They are all freelancers, which makes the factories’ capacity flexible. When the factories receive orders, they can recruit suitable workers within half an hour. Once the orders are completed, the workers get paid immediately and their employment relationship with the factory ends.

Most of Kanglu’s factories are of 200-300 square meters, accommodating about 35 workers at full capacity (30 sewing workers, 2 cutter, 2 ironer, 1 quality inspector). Their daily production capacity is around 1500-2000 pieces, depending on the complexity of the production process.

*Inside a Kanglu’s Factory

For example, for an order of 1500 sweatshirts, a Kanglu’s factory usually completes it within 40 hours. Here is the time flow chart:

Day 1 Morning

The clothing sellers confirm the style they want to produce, make its pattern and determines the processing fee.

Day 1 Noon to Afternoon

The sellers order fabrics from Zhongda Fabric Market. Look for processing factories in Kanglu. To attract the sellers, factory owners sit by the roadside, displaying the types of clothing they specialize in producing. Both sides usually reach cooperation deals before 2 p.m.

Day 1 Afternoon to Night

Fabric is delivered from Zhongda Fabric Market to Kanglu’s factories. Once the fabric arrive at the factory, cutters begin cutting the fabric according to the order style and quantity.

Day 2 Morning to evening

The factory owners, with sample clothing in hand, recruit sewing workers on the streets of Kanglu. After agreeing on the wages, the workers immediately start working in the factories. Each worker makes whole pieces of clothing by themselves. The factories have no assembly line.

Day 2 Night

Ironers and quality inspectors package the clothing.

Day 3 Early Morning (4 to 5 a.m.)

The order is completed and shipped.

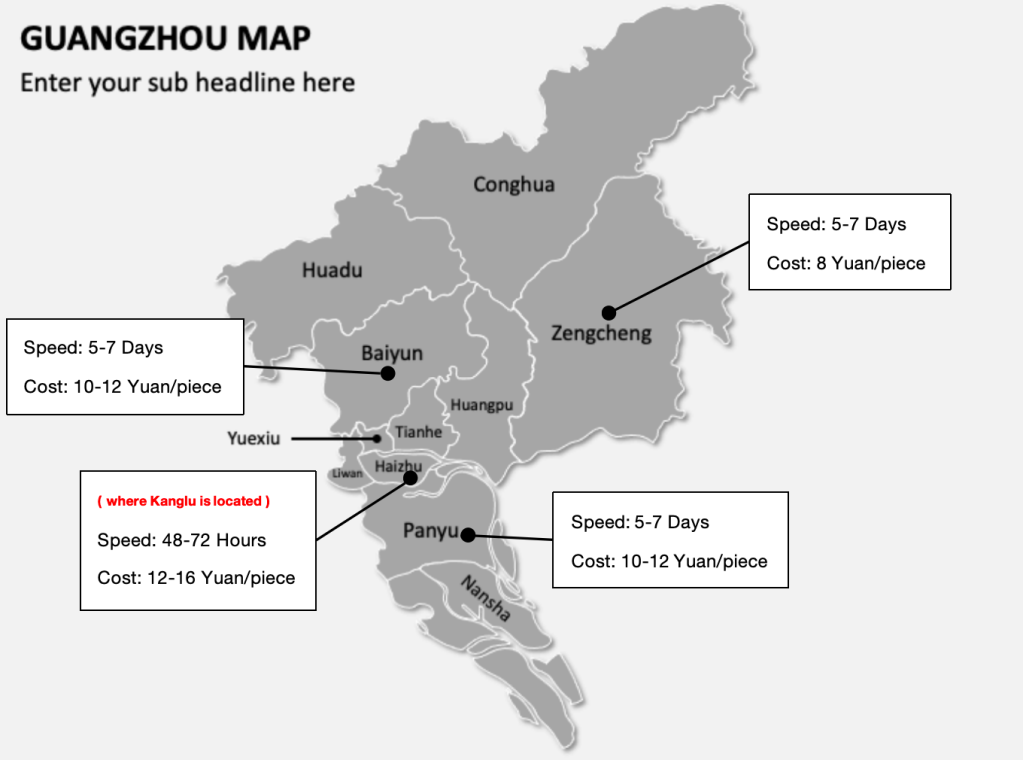

The speed of Kanglu’s factories is the fastest in Canton. Those of factories in other areas decrease, so is processing fee. Take an order of 1500 pairs of straight pants (cotton-made, with two pockets) as an example.

The map below shows the speed and processing fee of completing the order by factories of different areas. We can see a concentric distribution (with Kanglu as the center):

*process fee listed above does not include cost of fabric.

Basically, the speed of Kanglu’s factories is the fastest in Haizhu District (48 hours). Other factories in Haizhu District needs 72 hours, with labor costs 20% lower than Kanglu area.

Factories of Haizhu District is the fastest in Canton. In farther areas like Panyu and Baiyun District, factories takes 5 to 7 days to complete the order, because they adopt assembly line processing. However, the quality of finished clothing is significantly higher compared to that of Haizhu District.

Clothing sellers usually use this formula to calculate the processing fee they need to pay:

Total processing cost = Sewing worker cost * 2

Take a pair of cotton straight pants (with two pockets) as an example. Its total cost is 26 Yuan, with the fabric cost being 10 Yuan and the processing fee 16 yuan. The processing fee is calculated as follows:

1) The sewing worker takes 8 yuan ( this style includes two pockets, each pocket costs 2 Yuan, and the rest of the processing steps cost 4 Yuan )

2) Cutting, ironing and quality inspection cost 4 Yuan in total

3) The factory owner makes a profit of 4 yuan (to cover rent, utilities, and equipment costs)

This multiplier fluctuates with the peak and off-peak seasons of clothing production. During peak season, the processing cost charged by factories is 2.1 or 2.2 times the sewing worker cost. While in the off-peak season, to sustain their supply chains, factories charge around 1.8 times the sewing worker cost.

Supply Chain Disintegrating

Currently, Kanglu’s supply chain is disintegrating.

When you walk on its streets at 8 pm in November, you’ll find them packed with people.

This is not a good sign. According to the Kanglu’s work schedule listed above, workers should be busy sewing clothes, not wandering the streets. Rows of factory owners sit by the roadside looking for new orders, which should have been done in the afternoon.

*Factory owners sitting roadside looking for orders

The reason for their leisure is the decline in domestic clothing consumption. A seller of plus-size women’s clothing on Douyin app told me, “Clothes that used to sell for 70 yuan each, now can’t be sold even for 30 yuan.”

Lower consumption brings down the processing fee. After the rise of live-streaming e-commerce, Kanglu’s main source of orders has shifted from wholesalers to e-sellers on Pinduoduo and Douyin (their overseas versions are TEMU and TikTok Shop).

As the two platforms attract customers by low prices, the processing fee offered by their sellers is significantly lower than that of wholesalers – the former is basically 20% lower than the latter.

“Pinduoduo has the cheapest goods. Although they are cheap, its sellers usually have no quality requirements, so we can make a lot of items in a day, earning about the same money as before,” a sewing worker in the Kanglu told me.

However, things have changed this year. The major platforms have introduced “refund only” policies. Due to the high return rate of women’s clothing, the sellers have higher demands for quality. This means that it takes sewing workers longer to make a piece of clothing, reducing their daily output and subsequently their daily income.

Sewing workers in Kanglu typically want to earn 400 yuan per day. This means they would consider whether the fee paid by the factories allows them to earn 400 yuan.

“Before we start making clothes, we ask the sellers what quality they want. They can ask for high quality, but they have to pay us corresponding fee.” The sewing worker said.

“If they want high quality, I can only make 10 pieces a day. So they definitely have to give me 40 yuan per piece, which is 400 yuan per day. But if they want cheaper quality, I can make 100 pieces a day, even if the fee is 4 yuan per piece.”

The income of sewing workers has significantly decreased this year. A worker who has been working in Kanglu for eight years complained to me: he used to earn 8 yuan per pair of sweatpants (with ribbed cuffs, side seams, and double round pockets), but the fee dropped to 5-7 yuan this year.

Based on my interview, average monthly income of the workers has dropped from 11,000 yuan last year to just over 6,000 yuan in October this year.

Why the workers in Kanglu demand such high income? Because Kanglu is in downtown Guangzhou. The cost of rent, food, and social activities for these workers amounts to 3,000 to 4,000 yuan per month. Many of them also have to send money back to their parents and children in rural areas.

If they can only earn 7,000 yuan a month, it would be more cost-effective for them to work at places with lower living costs.

Workers are leaving their jobs. I joined a WeChat group of workers in Kanglu. This group gathers hundreds of casual workers and factory owners. Until the end of last year, this WeChat group was still full (500 members), but the number has gradually decreased to just over 300 this year.

the Pending Demolition Plan

The pending demolition plan is another reason for Kanglu’s disintegration.

At the end of last year, the Haizhu District government introduced a demolition policy to tear down Kanglu area and rebuild it as high-end residential buildings and shopping malls.

However, only 1/10 of the area have been demolished so far, because of the sluggish real estate market in China. The rest of the area is difficult to be demolished, because many of Kanglu’s landlords are not satisfied with the plan.

According to information I obtained, the compensation proposed by the government is to offer resettlement housing according to the owners’ building area. This has made many landlords feel that their interests damaged.

Mr. Liang, a property investor who owns more than 6000 square meters of factory buildings in Kanglu, told me: “If they compensate me according to the current standard, they have to give me 40 apartments. Each one can rent for up to 4000 yuan a month, totaling 160,000 yuan a month. This amount is less than half of what I get from renting out the factory building.”

The demolition plan also left factory owners uncertain about their future. In Kanglu, you can see advertisements posted by factory owners for factory transfers.

*advertisements for factory transfers.

The government has offered new place for these factories – Qingyuan City, located 90 kilometers north of Kanglu.

However, no one believed the factories could regroup there. If the factories were to relocate in Qingyuan, their orders would go to other factories located in downtown Canton, which are much more conveniently located compared to Qingyuan.

Xintang town also hopes to attract these factories, which is 30 kilometers east of Kanglu. Xintang was once the largest jeans production base in China, but the serious environmental problems caused by jeans production led to the relocation of the jeans industry. This leaves over 2 million square meters of vacant factories, with a vacancy rate of 80%. Real estate developers in Xintang hope that the factories from the Kanglu district can fill the void.

“The factory market in Xintang is not good, the vacancy rate is too high, and the arrival of processing factories from Kanglu supply chain can revitalize these properties,” Lin Yuehua, the general manager of Xintang Clothing Trade City told me.

However, no factories have chosen to relocate there, because Xintang is also remote. Most factories opting to leave Kanglu have moved to other urban villages in the Haizhu district. This at least allows them to maintain some speed advantage compared to their competitors.

What’s Next?

Facing the decline of the Kanglu factory, both the upstream (fabric suppliers) and downstream (clothing sellers) of the supply chain believe that this has little impact on them.

For Zhongda fabric market, the fabric demand from the Kanglu area accounts for less than 5% of their total demand.

“We do business nationwide. The sellers served by the Kanglu supply chain are small in scale. Even if they come to me for fabric every day, they can’t match the volume of a single order from a big customer,” a fabric wholesaler in the Zhongda fabric market told me.

Even if the factories in the Kanglu area regroup in a new place, they will still come to the Zhongda fabric market to purchase fabric, as there is no other fabric market in Guangzhou that can compete with the Zhongda fabric market.

“No matter where these processing factories relocate, they need to obtain fabric from me.” The fabric wholesaler said. “Suppose they form a new supply chain in Xintang or elsewhere, our secondary wholesalers will set up stores there, so they are still my customers.”

“Only if their fabric demand is large enough to directly cooperate with fabric factories, we will consider moving our headquarters closer to them. This will not happen in the short term.”

Clothing sellers are not worried as well. Even if Kanglu supply chain collapses, other factories in Canton can complete their orders.

A female clothing seller on Douyin told me that the factories in Kanglu only make up 1/20 of her more than 1,000 factories. Their role is to produce styles with small quantities (around 100 pieces) for testing sales; if the demand for a style is large, it will be handed over to larger-scale factories. Her supply chain is distributed in Haizhu District, Sanyuanli, and Panyu District of Guangzhou City.

“The speed of Kanglu’s factories is faster, and they can handle small quantities because there are many workshops. Factories in Panyu are assembly line factories; one piece is divided into several workers to work on. Their production speed is slower, but the quality is better.”

-

欢迎使用 WordPress! 这是一篇示例文章。 编辑或删除它,开启您的博客之旅。 如需在此处添加更多内容,请点击左上角的小加号图标。 在这里,您可以找到现有的 WordPress 区块和样板选择,可满足您在内容创建方面的各种需求。 此外,请别忘了查看“列表视图”:点击加号图标右侧的图标,您就会看到一个规整且易于查看的列表,其中列出了您文章中的区块和样板。

-

欢迎使用 WordPress! 这是一篇示例文章。 编辑或删除它,开启您的博客之旅。 如需在此处添加更多内容,请点击左上角的小加号图标。 在这里,您可以找到现有的 WordPress 区块和样板选择,可满足您在内容创建方面的各种需求。 此外,请别忘了查看“列表视图”:点击加号图标右侧的图标,您就会看到一个规整且易于查看的列表,其中列出了您文章中的区块和样板。

-

欢迎使用 WordPress! 这是一篇示例文章。 编辑或删除它,开启您的博客之旅。 如需在此处添加更多内容,请点击左上角的小加号图标。 在这里,您可以找到现有的 WordPress 区块和样板选择,可满足您在内容创建方面的各种需求。 此外,请别忘了查看“列表视图”:点击加号图标右侧的图标,您就会看到一个规整且易于查看的列表,其中列出了您文章中的区块和样板。

-

欢迎使用 WordPress! 这是一篇示例文章。 编辑或删除它,开启您的博客之旅。 如需在此处添加更多内容,请点击左上角的小加号图标。 在这里,您可以找到现有的 WordPress 区块和样板选择,可满足您在内容创建方面的各种需求。 此外,请别忘了查看“列表视图”:点击加号图标右侧的图标,您就会看到一个规整且易于查看的列表,其中列出了您文章中的区块和样板。

-

欢迎使用 WordPress! 这是一篇示例文章。 编辑或删除它,开启您的博客之旅。 如需在此处添加更多内容,请点击左上角的小加号图标。 在这里,您可以找到现有的 WordPress 区块和样板选择,可满足您在内容创建方面的各种需求。 此外,请别忘了查看“列表视图”:点击加号图标右侧的图标,您就会看到一个规整且易于查看的列表,其中列出了您文章中的区块和样板。